SAACKE GmbH Integrates Scandinavian Boiler Service (SBS)

SAACKE's history began in 1931 in Bremen, Germany where the factory was established. A family-owned company originally started as a burner maker and is now in its 4th generation of ownership.

SAACKE is a pioneer in many combustion technologies in industrial applications such as rotary cup atomizing burners. SAACKE burners were the first to burn coal dust and the innovation has always kept SAACKE at the forefront of the industry; setting standards for others to come. SAACKE burners are still designed and assembled in the original workshop in Germany and there are thousands of delivered units already in operation in industrial facilities, infrastructural facilities, seagoing vessels and offshore assets.

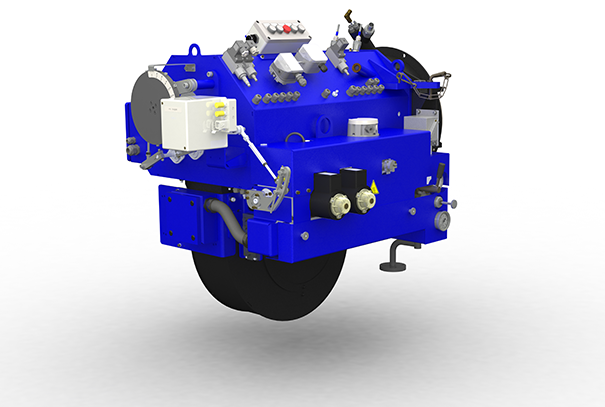

SAACKE's legendary SKVJ-M rotary cup burner

In 1999 the company expanded the portfolio in the shipping business by purchasing the Croatian boiler manufacturer TPK from Zagreb and in 2001 by purchasing and incorporating boiler production facility VKKMB from Kiel, Germany in order to utilize the resources and experience of these two boiler makers in delivering burner and boiler packages to the new buildings in European shipyards.

In the mid-2000s when the shipbuilding shifted to the East, the company increased its presence in the new building hubs in China, Korea and Japan. And in 2009 the manufacturing facility in Qingdao was set up to respond to the increasing demand from the Chinese and Far-East yards. Since 2012 the entire boiler production has been shifted to China where SAACKE is maintaining a fair market share.

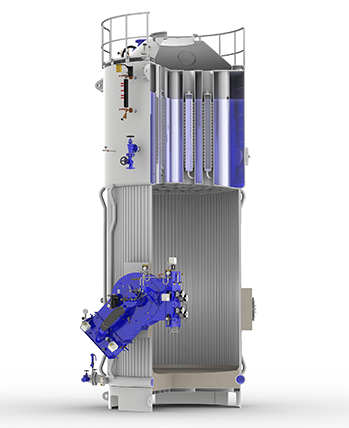

SAACKE's FMB-VL with pin tubes

The company has been working to expand their services range and customer distribution channels and capacities ever since. Kiel remains the main design center and the Zagreb facility has been repurposed for internal needs for burner part manufacturing and assembly as well as fabrication of the components for boiler repairs.

Also, SAACKE is the inventor of the Gas Combustion Unit technology, for LNG carriers. As a specialist in combustion systems for seagoing vessels, SAACKE makes it possible with the GCU to transport liquefied natural gas (LNG) safely and reliably at sea.

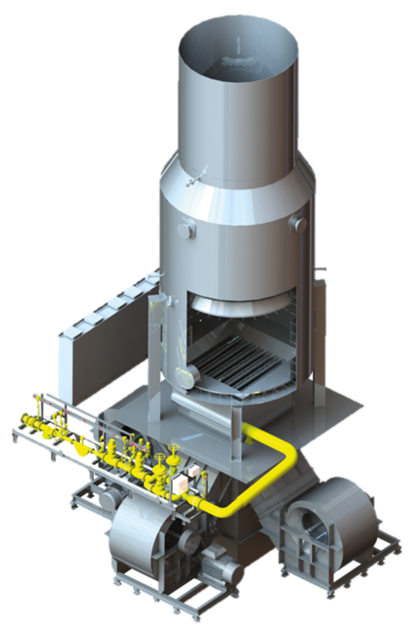

SAACKE's GCU evo

Strategic steps were made in 2022 when Scandinavian Boiler Services (SBS) was fully merged and incorporated into the SAACKE group and now can jointly offer a full scope of boiler and burner repair of all brands, conditions and ages.

SBS was established back in 1995 in Florida as a US-based company to serve the local fleet of cruise liners and tankers. The company has since expanded to various locations around the globe in Denmark, Singapore, Croatia Vietnam and China. SBS expertise has been recognized by many ship owners and ship managers over the years. As an experienced and reliable provider of comprehensive care for burners of all brands and types, SBS has been awarded by many to be the exclusive provider of boiler & burner automation services for their vessels.

SAACKE as a long-time OEM and SBS as a reputable boiler and burner service provider have joined forces for providing optimal coverage with boiler repair and burner services in all major shipping hubs across the world.

SAACKE-SBS, by combining each other’s vast experience, clientele and global coverage aims to provide to the shipping industry reliable repair and retrofit services as well as to supply the highest quality materials and spares for almost any make of boilers and burners for many years to come.

Hereunder is the SAACKE–SBS delivery program:

IN-HOUSE DESIGNED AND PRODUCED EQUIPMENT:

- Well-known quality products and approved design

- Oil-fired, Combined and Exhaust gas boiler/economizer

- Up to 110 t/h steam capacity

- Approved by all classification societies

- Optional On-Line monitoring for remote assistance

- Worldwide service network

GAS COMBUSTION UNITS for the safe transport of LNG

- Worldwide service network

- BOG range from 0,3 – 4,5 t/hr Methane

- Optional On-Line monitoring for remote assistance

RETROFITS Design or Retrofit of Boiler & Burner Management System

- Retrofit of obsolete equipment to high-quality products

- Re-design of boiler systems

- Full project management

- For older boiler control systems based on obsolete key

- For parts like PLCs we developed a modular system suited for most burners and boilers. The system can handle multiple boilers with multiple burners, and the technology is already installed on several large tankers.

SERVICES:

SERVICE ON CONTROL AND AUTOMATION SYSTEMS

- Service or Repair

- Upgrading

- Supply of new control or automation systems

- Inspection

- Burner adjustment

- Commissioning

- Supply of new burners

- MDO / MGO upgrade

- LSGO conversion

- Training of crew

- Maintenance plan

- Health Check

- Annual or pre-docking inspection

SERVICE ON ADDITIONAL EQUIPMENT ONBOARD

- EGE protection systems

- Inert gas systems

- Nitrogen systems

- Smoke density monitors

- Oxygen analyzers

- Oil mist detectors

- NOx, CO, CO2 and SOx monitoring

- Inspections

- Repair of all types and makes of boilers

- All works are class approved

- Production of all types of boiler tubes

- Service on GCU and burner

- Inspections

- 24/7 first-class service

- Commissioning

- Boiler service agreements

- GCU service agreements

EMISSION CONTROL AND GAS ANALYSIS

- Smoke Density Monitor

- Ambient Oil Mist Detector

- Inert Gas Oxygen Analyzer

- Pre-docking Services

- Ad-hoc 24/7 Services

- Annual Service Packages

- Online Monitoring Services

- Safety and Health Checks

- Condition Inspections

- Boiler performance checks

- Emission control and adjustment services

- Fuel and Energy saving services

- Plant Analysis

- Condition-based maintenance services

- Boiler repair and supervision

- New build engineering services

EEXI FUEL SAVING PROGRAMS INCL. DOWN-SIZING AND MODIFICATIONS TO MEET YOUR GREEN GOALS

- Low load mode for aux boilers

- Aux EGE system

- Oxygen trim for burner control

- Power Management for boiler

- FD fans and pumps

- Electrical steam generators

- Spare parts for all types of Boiler and burner equipment

- Competitive price level

- Deliveries worldwide

- Response to inquiries within 24 hours