Hoover | Tech Oil Products Announcement

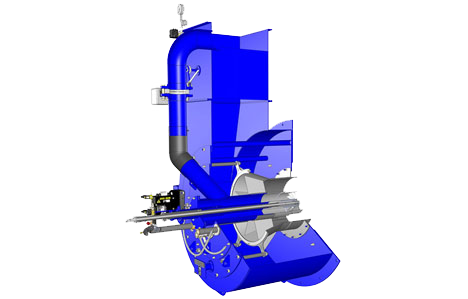

Hoover - Tech Oil Products is the quality leader in MARPOL Compactor and Baler waste management equipment and Intermediate Liquid Bulk (IBC) storage tank solutions. With the rugged requirements of the maritime industry all of equipment must stand up to the most challenging environments so we have taken the time to design and manufacture all our equipment in stainless steel, with options for explosion proof environmental and hazmat.

Our quality is why we have the best warranty in the industry 10 years manufacture and 5 years components. Our commitment to you is excellence in customer service and quality.